The Waterwheels

There are two waterwheel pits in the mill. The Bill of Sale in 1834 describes the wheels as they were then –

On the Ground floor consists of a water wheel on the east side of the mill, 22 feet diameter and 7 feet 8 wide, with iron floats, arms and rings. A ditto on the west side, 23 feet diameter and 8 feet wide, with wood floats, arms and rings.

But was it built with two? In volume 1 of General View of the Agriculture of the County of Essex published in 1813, two mills are described –

Langford – Mr Stammer was so obliging as to shew me his mill, and a very fine one it is; has ten pairs of stones; working six or four. One water-wheel twenty-two feet four inches diameter, and nine feet wide; fall of water ten feet and an half. The whole work so smooth, that the noise is little.

Beeleigh ( Bealy in the book) – Mr. DUNKIN, of the beautiful new-built mill at Bealy, had the goodness to go over it with me. The wheel is twenty-four feet diameter, and receives the water a little above the centre: all the barges come under the mill for loading and unloading, the sacks drawn up or let down with great expedition, and all the machinery, and contrivances for abridging labour, appear to be disposed to much perfection.

This was a report for the Board of Agriculture and one might think that if the mill had two waterwheels that it would have been stated. Unfortunately, the number of stones is not mentioned.

In 1840, one of the wheels and associated machinery was sold by auction –

The machinery of one side of Beeleigh Mill, comprising a water-wheel, 24 feet diameter, 8 feet wide, with 80 iron floats, and water-wheel shaft with cast iron cap; 16 feet pit wheel with iron segments; 5 bridge trees, with carriages, lighter-irons, &c. &c.; 3 feet-10 iron wallower nut, with suspending irons, &c.; 11 feet 9 geared spur-wheel, pair 4 feet 6 French stones, 25 feet upright oak shaft, with plumber, block, &c.; geared crown-wheel, riggers, jumpers, stiff irons, driving irons, dressing machines, and various other machinery.

It is not known if either of the wheels survived the fire of 1875.

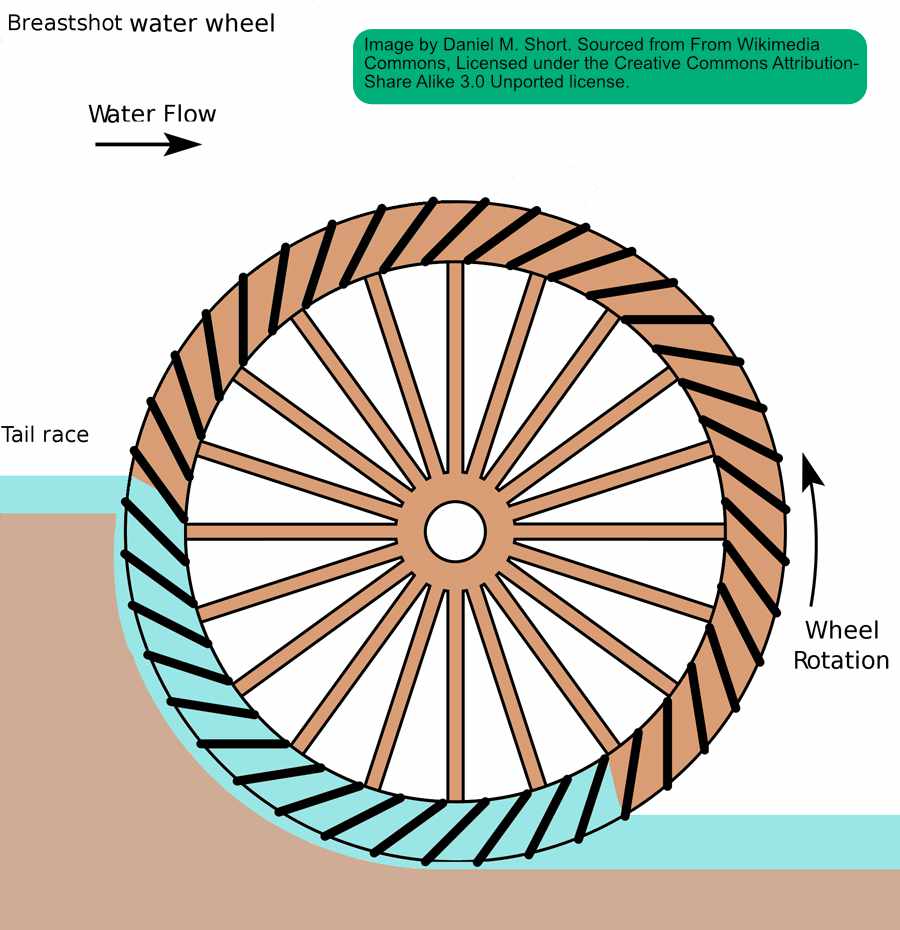

The wheels received water from the millpond slightly above centre, known as breastshot –

Since the flow of the river Chelmer through the mill, the wheel pits have become heavily silted.

The North (or East) Wheel

The housing for this wheel has been modified since the fire. A colony of bats were present in the steam mill building when the restoration was first considered and a new home was built for them above the north wheel.

The South (or west) Wheel

The interior of the housing for the south wheel is less visible to visitors, except by peering through the access, with its relatively recent safety bars.

c2011. South wheel entrance. Through the bottom of the opening can be seen the arch of the feed from the millpond. To the left would have been the mechanism for raising and lowering the penstock.

Back to Beeleigh Mills